I found this little gem on a swedish electronics ”for sale”- forum. It’s a kit made from MDF wood that another member cut on a huge CNC router. It’s called the ”lillasyster”. This one has never been used as it’s not completely finished. Instead it’s been sitting down in a cellar for a couple of years. I couldn’t resist picking it up as I got a really good price on it.

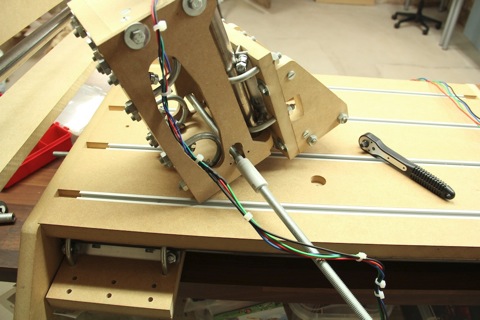

The machine when I got it:

Three FL57STH51-2804B Stepper motors

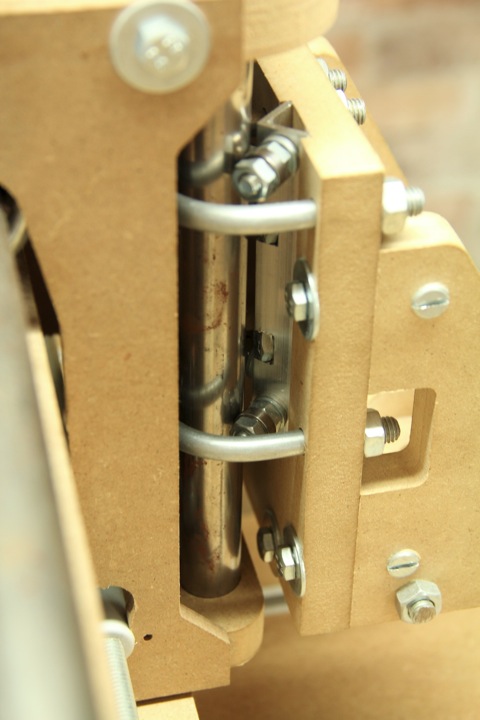

A pic of the clever ball bearing system.

No slop but it’s still really smooth.

The stepper motor controller. Also designed by the used ”Jojje”.

Since the machine is made from MDF wood, it definitely needs to be treated before usage or it won’t last very long. The machine also needs to be looked over after spending so much time in the basement.

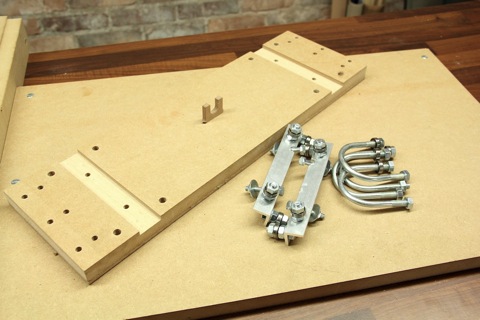

Started taking it apart.

I’m going to paint the whole machine but as MDF is infamous for absorbing an infinite amount of paint so I treated all the wood with white wood glue mixed with water before applying the paint.

I bough a special paint made for painting car rims. It’s supposed to be really tough.

Several coats of paint later.

After sitting down in the cellar the steel pipes had rusted slightly. Some steel wool and silicone spray later:

Shiny and really slippery. It also ads protective coating to prevent it from rusting again.

Shiny gold.

The black and gold looks pretty good together.

To make the bearings last longer I added some grease to them.

Jummy grease.

I also made some rubber washers.

Fitted back on the machine.

Almost put back together.

I’m pretty satisfied with the finish.

The router. A Kress 800 FME. It’s like a dremel on steroids! 800W of cutting power.

It works! It took a fair bit of reading and a bit of tweaking but in the end I got it to cut glass fiber really well.

Here is a video of the CNC cutting some tricopter frames:

The cutting area it’s capable of is roughly: 305*490*80mm

This should make it quite a lot easier to experiment with different designs.

very nice?

Are also cutting carbon? And what type of bits are you using?

Nice concept!!! Well defined article, Keep up the good work…

Sale of CNC Router http://www.routercenter.com/

Hello david. Great job! With this CNC. Im super impressed. I would realy really love to make it myself. Do you maybe have the measures so i can cut the pieces like you did ? Please. please send me on my email I need it for my school project.. [email protected]

Thanks!