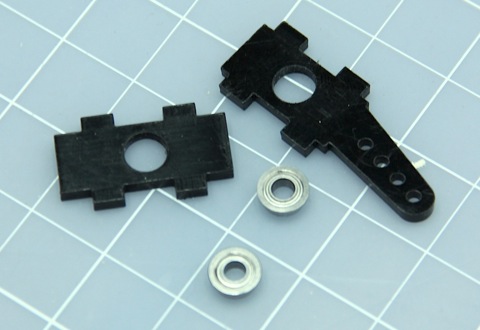

My friend Tim Nilson, the owner of FPVmanuals.com has created a tricopter kit based on my design. The kit includes all the hardware, except for the wooden arms and zip-ties, that you need to build a tricopter. A thing that makes this tricopter kit unique is the materials it’s made from. The main body and motor mounts are made from delrin plastic, which is extremely though. The camera tray is made from a 3mm bamboo plywood. The top protective plate is made from orange tinted acrylic. All these different materials together make an awesome kit. Let’s start building.

The parts

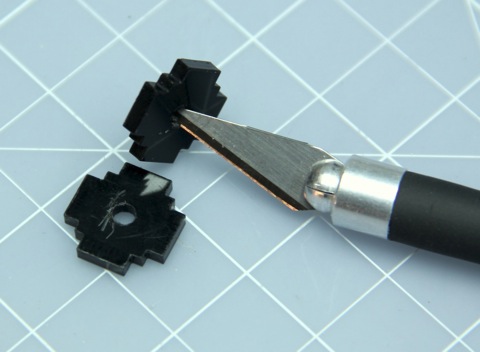

This piece is a jig. It’s made to ease the cutting of the notches in the wooden arms needed for the nylon screws.

Simply cut a V-shaped notch with a knife.

After cutting the notches and drilling the holes I painted my arms using a black spray paint.

Time for the yaw mechanism. These two ball bearings needs to be press fitted in the holes.

The bearings fits really snug.

Place the two pieces with the bearings facing outwards. This will ensure that the bearings will never come loose.

I’m really impressed with the manufacturing quality of the kit. All pieces fits perfectly together.

These pieces will hold the aluminum axel. They are designed to hold the axel tightly and can be a little difficult to press on. To make this easier bevel the edge of hole slightly. Do not increase the size of the hole it self, just the edge.

Press on and ready to be mounted.

The pieces fits perfectly once again.

The tail ”box” done.

The motor mount and servo mount added as well. This yaw mechanism is extremely smooth and completely free from slop.

The bag of screws and other mounting hardware that’s included in the kit.

Two holes needs to be drilled through the wooden arm to mount the tail ”box”. The screws and nuts included are made from nylon, which means they are very light but also strip out very easy. Only tighten the nuts using your fingers. They will be tight enough that way and there is really no chance of you stripping them unless you have superhuman pinching strength.

Time to assemble the motor mounts.

I’ll be using the good old 2213N 800Kv Brushless motors I used in V1 and V2. In fact I’ll be using the ones I rewound. Funny side story: These motors were mounted on the tricopter I crashed into the ocean in Cancun. I discarded the motors in Chads ”box of stuff that’s probably broken and can be used for spare parts” as the bearings had rusted. The second time I returned to the US I saw the motors still laying in the box, so I decided to refurbish them by fitting new bearings, axels and bells on them.

All motor mounts in place.

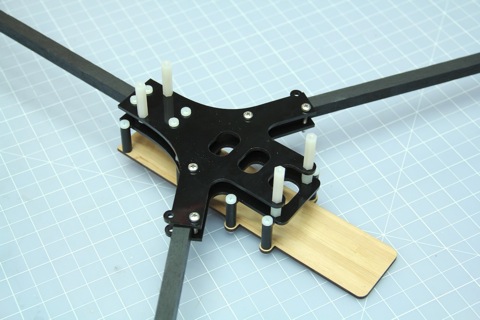

Time for the main body.

Tail boom in place.

Camera tray made out of laminated bamboo in place.

The two front arms in place. Note that metal screws are used.

Time to mount the servo. I used a BMS-385DMAX Digital Servo (Metal Gear) as usual. The servo linkage is included in the kit as well.

Remember to add a dab of hotglue to the servo tray. This will make sure that it stays in place even after the hardest of crashes.

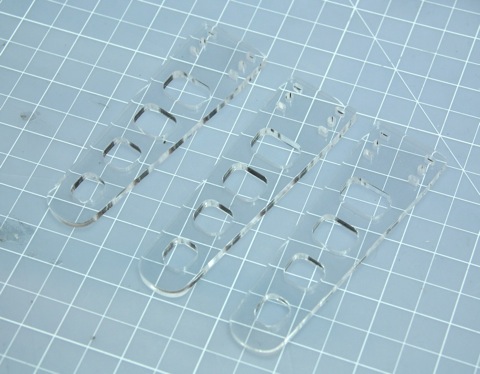

Lexan landing gear.

The landing gear can either be mounted with screws or zip-ties. I would recommend zip-ties as it makes them ”break away”.

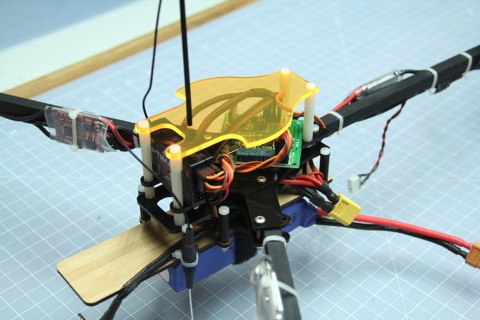

Electronics in place. I used a HK kk board, 10*4.7 APC props and TURNIGY Plush 18amp Speed Controllers.

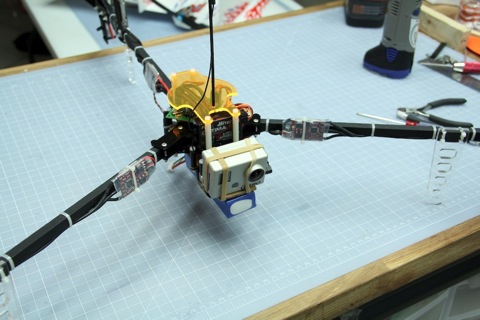

All it needs now is a GoPro.

The orange top plate. Looks really nice in real life, as well as protects the electronics.

I like to have my GoPro tilted slightly downwards so I added a small piece of balsa.

All mounted and ready to go!

Here is a video where I use the FPV Manuals tricopter:

The kit can be bough at getfpv.com

David, thats me again, the Brazilian coming with LOLED questions…

I just bought few parts of that tricopter from fpv manuals, and I just wondering if I mix those 2 projects, the tricopter and the QAV500,

creating the dirty and clean parts of the frame, using those silicone bumpers actin with compression (mounting control board and camera on the top frame), and not with suppression as its original project… Do you think If I use shorter( I mean really short, as seen on QAV500), and using

the compression dampening sister, that ill be a good project? On shorter arms are a big NO NO to tricopter?

I see no reason why it wouldn’t work 🙂 Go for it!

Shorter arms means quicker response, but can also mean less stability.

Other thing, How do I edit my posts to correct some words I just wrote wrong? Sorry about my english!

Dadde, I’m designing my new frame after this- but I do have one question: How is the yaw mechanism sandwiched together? If I’m directly mounting the motor on, would I put my screw from below the bottom motor mount through a nylon spacer and then mount to the motor? How long are the nylon spacers on the motor mount? Thanks

They are 10mm long. Yes you put the screw through the bottom, through the spacer and then into the motor

Hi, I am building my own with your frame and wonder if somehow you could sell the yaw mechanism.

Thanks

Hi, I am going to build one of these tricopters, and was wondering how do you wire it? I have been doing lots of diy lately, but am totally new to RC.

Thank You!

P.S: I was also wondering about how you program a tricopter?

David, I’m getting ready to purchase parts to build a tricopter. One item I’ve not been able to find is the dimensions and lengths of the arms. Can you provide that info? Thanks.

Bud

High Bud,

the dimensions are to be found here (picture no. 4 from 5)

http://rcexplorer.se/product/10x10mm-woven-carbon-fiber-arm/

Sincerely yours

Nuritri

David,help me for specify the motors

how you feels for this motor:

Turnigy L2210-1400 Bell Style Motor (210w)

Turnigy DST-1200 Bell Motor 1200kv (160w)

Turnigy L2210C-1200 Motor (150w)

what more recommended for this project and how value of current (A) of ESC ?

Thanks,