The J37 Viggen is my absolute favorite airplane of all time. I’ve been thinking of building one for a long time, but I didn’t just want to build a flat foamy. I wanted to do it’s awesome curves meaty fuselage justice. So I decided to cut one out of 4 inch thick Bluecor using a hotwire.

Here is the plans to the formers used in this build: EDF Viggen Plans

Since Chad didn’t have a hotwire in the basement, I had to build one from scratch. (How can people live without one?)

To do this build I didn’t really need a big hotwire bow. I rather have a small, light one that gives me great control over the fine movements and doesn’t make my arms tired.

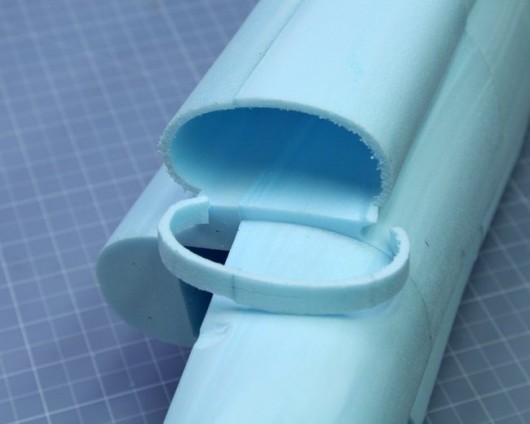

Very basic shape. I didn’t feel the need to glue 1/2″ PVC pipe pieces together. The friction seems plenty strong.

The wire I use is 0.4mm thick Nikrothal 80. A nice thickness for this kind of work. It also doesn’t expand as much as other hotwires when it heats up which is nice. Regardless of what wire you get you will most probably not going to be able to solder it. To get around this problem I cut a small piece of brass tubing.

I then slip the tube over the wire and clamp it down hard using a pair of pliers.

The brass is soft and makes a great electrical bond to the wire and it’s super easy to solder to.

One thing you don’t want on your hotwire bow is a slack wire. To achieve this I simply pushed the two arms inwards when I attached the wire. This creates an outward tension in the bow that keeps the wire taught even when it get’s hot.

I wanted both wires to come out the same end so they don’t end up in the way when I’m working. I simply fed a piece of wire through the inside of the bow.

Soldered toghether. Nice and clean.

Close up of the solder joint.

To control the temperature of the wire I used a BRUSHED spedcontroller and a servo tester. That way I can easily control the voltage aplied to the wire and thus control the current flow, which is what is turned into heat. I^2 * R = Heat dissapated in the wire

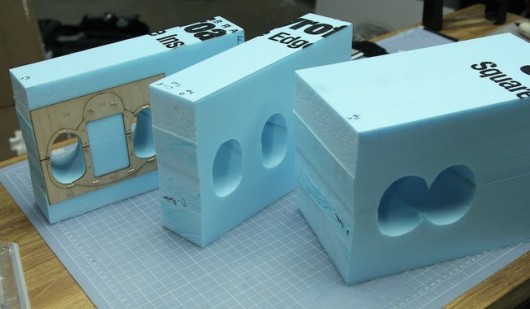

I started out by cutting two blocks of 4″ foam

A tip is that the hotwire bow cuts perfectly straight down with the help of gravity if no external force is acting upon it. Just let it hang and make sure the power wire doesn’t affect it.

Used building needles to pin the formers down.

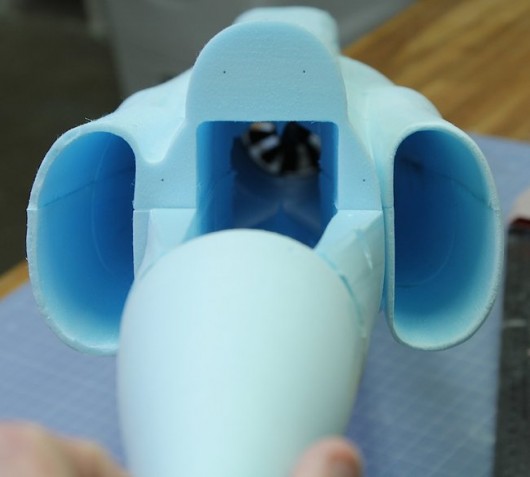

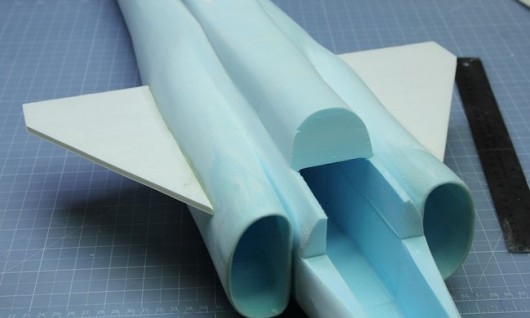

Started by cutting the air duct for the entire F-H and C-F first

Then I cut the big pieces into the individual sections.

And cut the contours of each piece.

Video about the hot wire cutting process:

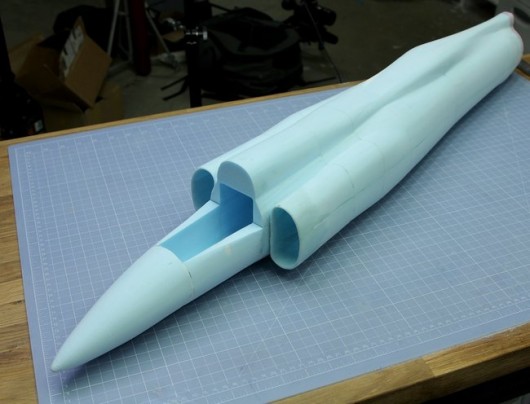

The F-H piece was a bit short so I had to add a piece of foam to the end.

Nose cone before shaping.

I used a power drill and some sand paper to shape it into a cone shape.

Done.

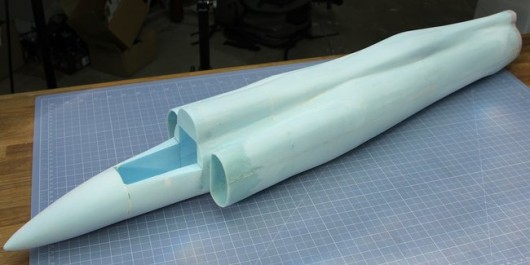

All pieces glued together.

Nosecone fits pretty well

ChangeSun 10 Blade 70mm EDF unit

To get the CG correct I mounted the fan as far back as possible.

Time to fix the intakes.

Removed around 5mm.

Sanded away the material between the air intake and the fuselage as well as smoothed the intake edges.

Before and after.

The intake was way to fragile being that thin so I glassed the edges.

Now there nice and strong.

Sanded the whole fuselage.

Added a layer of light spackle.

Sanded it again.

Nice and smooth.

Cut the wing.

I strengthened the radar detectors on the wings with a 2mm carbon rod.

Installed the canards.

Notice the positive angle of attack.

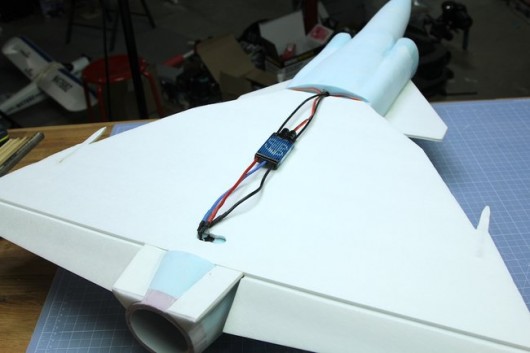

Installed the wing.

Time for the servos. Glued using hotglue to the wing.

A detail that really transforms the plane is the wing fillers. Looks great and hides the servo wires.

Servo wires going into the fuselage.

Added the bottom details to the exhaust.

I added a plastic tube on the inside of the exhaust to minimize the drag an add strength.

Speed controller installed.

The bottom plate covers the wires nicely.

To add some scale detail I added weapon hard-points made out of balsa spars.

Installed the rudder

Control linkages in place and ready for the first flight.

It flew awesome! Time to hand it over to Chad and have it painted.

Just need some decals!

The numbers are cut from orange vinyl. All other decals were printed on normal sticky back paper used for shipping labels on a laser printer and then spray painted with a layer of clear coat.

Canopy held down with magnets.

Up, up and away

Video:

This is awesome! I never knew that I needed a Hotwire!

What kind of glue did you use to joint the foam together?

Hotglue

David why you dont sell the laser cut formers so we can cut it by ourselfs whitout figure out how to mare the formers “p

Very awesome plane!

The cost of the formers would be quite large as you have to use so much material and the cutting time would be long… I wish I could offer them to people as the plane really is amazing.

Which battery size do you use and howndo ypu gwt tje correct gravity center?

Flew mine on a 4S2200 and a 4S3000

The CG is located just a tad behind where the main wing meets the fuselage

Supernice foamy.

On my way to make one myself.

Curious though about your ESC? What do you use since you are parallelling the batteries.

80A or 100A ESC? bigger?

A 60A, the ESC doesn’t need to be larger because you’re paralleling batteries. It’s just like running a larger capacity battery.

A few questions:

What do you use to glue the fiber coth at the intakes?

How do you fix the batteries inside the cabin so the dont move?, I see the hole goes all the way to the exhaust. Is it posible to fly it with just one battery? Thanks!

30 minute “finish” epoxy.

Velcro

Yes, one battery works great, I just didn’t have one the right size 😉

Thanks, I guess you place the batteries aligned along the plane so the wheight is more distributed, this could be better for the flight performance right?. I was planning to build mine with 2 4s 2800 so the total batt weight is around 630 gr. I guess thats the necessary yo equilibrate the motor weight, correct me if I’m wrong. If using one it would have to be around this weight? I would like yo know estimated flight time and batt weight with the ones u used and if it would be better using just one of bigger capacity. Thanks.

One 4s 3000 or a 4s 2800 is a great size. Will give you plenty of flight time.

Hi again.

Did you get your plywood forms lasercut out or did you make them yourself?

I was thinking of getting the plans to a local lasercutter factory to help me with the forms but they wanted the plans in vector shapes.

Is it possible for you to alter the PDF and put ip up again with vector shapes?

Or… can you give a good suggestion how to apply those printouts on a plywood? Sprayglue? hotglue? whiteglue? Any other way?

I lasercut them (too lazy to do them by hand :D)

The PDF is in vector format. It’s drawn in Illustrator, Open it and export it to any format you wish

What glue did you use to glue the individual pieces together?

Hotglue

Actually, what glue do you use to glue two pieces to make one piece? I have two 8×4 feet 2 inch thick foam. I can’t imagine hot glue; too much service area to cover. The hot glue would try too quickly.

White Gorilla Glue works well for this

All right, thanks!

I found white gorilla glue to not work, because it expands. This is REALLY BAD. I could not cut through the glue with my wire cuter easily either.

The foam I used was 4 inches thick.

If you need to glue them together, use 3m77 and then reenforce the pieces after cutting them

Thanks David!!! This worked amazingly well.

OOO, oops, the next day I saw that the 3m77 melted the foam actually… So what I did was put three small beads of glue on the two pieces and reinforced that afterwards. That worked pretty well, and now done with the fuse! Looks great, but what EDF would you recomend? I know you used the Changesun, but I can’t find it anywhere! Can you give a link? Thanks for all these questions.

OOO, oops, the next day I saw that the 3m77 melted the foam actually… So what I did was put three small beads of glue on the two pieces and reinforced that afterwards. That worked pretty well, and now done with the fuse! Looks great, but what EDF would you recommend? I know you used the Changesun, but I can’t find it anywhere! Can you give a link? Thanks for all these questions.

Hi David,

Where did you buy your 4″ foam? I’m assuming somewhere locally while you were in Ohio, but I can only find 2″ thick foam at building supply stores around here. If I had to join them with Loctite 300 spray adhesive, would that be sufficient to bond 2 sheets of 2″? What do you recommend for re-enforcement?

Tack så mycket!

I ordered it from somewhere. Can’t remember from where. It was someplace in the states. Took about a week to arrive and it was pretty dented and smaller than the spec.

Spray adhesive should work as long as you glass the intakes. The foam is pretty thin there. Take it easy when cutting. Very little tension on the string when you cut the thin sections.

AND what size are the plans? I need to tile them for my puny printer. Do you have a tiled version????

There are no plans for this version, but there is the Foam Board David designed for Flite Test on their site, and they are available as tiled

The plans are in 100%, the wingspan is 700mm if you get that right everything else should be correct.

I figured out how to tile them, and cut out the templates. Can’t wait to start.

heyy how did you tile the pdf really confused

well, may be david will reconsider having the forms for the in his store.

orat at a minimum come up with a tentative price and see how many bites he gets. it is such a beautiful plane/model that most likely he will have the sames supply problem as with the amazing tricopter.

is every else fails, how about providing a link to the drawings ?

Which motor do you use in the setup? Would I get enough thrust with 430 w power or better go with 630 w?

Go with the 630W More power is always more fun 😀

i am still hoping to hear from David about the cutting templates…..

or, did i miss them ? I already own the FT version, but would rather build the Foam one.

David were are you ?

@David

Do You have the plans in a cad version too so we could cut it ourselves with a router or lazer ?

/Ulf

Can you show us where you have CG on this “Sport scale Viggen” and it should be great if you can show it on the blue print too.

/Kjelle

David, Where did you fit the receiver, inside por outside the cockpit?

On the inside

Can you give some hint to cut out the A-B bit (the cockpit) in a “smooth” way.

That is giving me a headache to get it right.

Low temp and go slow is how I did it

Muy bueno el viggen !!! Saludos de Argentina !

Very good viggen !!! Greetings from Argentina !

How long were each of the sections because I want to build one but can’t find any instructions to do it. Your help would be appreciated David

Measure the distance between formers in the PDF plans. There is a line where each section starts and ends. You have the scale by the wingspan being 700mm. Instructions on how to cut and in what order is also in the PDF plans.

I can’t really find any 4 inch thick foam where did you get yours

Thanks

I can’t really find any 4 inch thick foam where did you get yours

Please reply

So where did you buy your 4 inch thick foam

Hello! Ive started with cutting but Im confused with x and z. What are x and z pieces?

Which ones?