A friend of from www.fullkontroll.se asked me to build a complete FPV setup for him. I got to choose what gear and he would get for me. That sounded good to my ears, so I agreed. Here is the shopping list:

The airplane

Airframe: Multiplex Twin Star II

Motors: 2 Above All 2813-18 1022kV

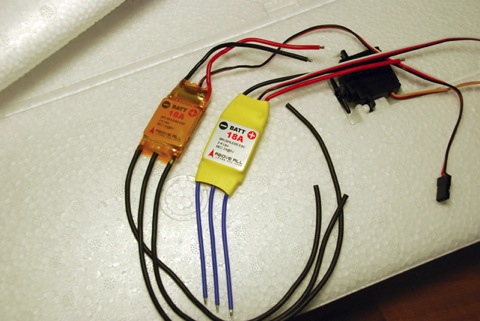

ESC’s: 2 Above All 18A v2 ESC’s

Battery: 3S 3600mAh 10-15C Electric Power LiPo

Servos: 4 Power HD-1160A Servos

Props: 2 8*6 APC props

All from www.fullkontroll.se

The FPV setup

Goggles: Rvision-D

VideoTX: 300mW 1.3GHz

VideoRX: Dual output 1.3GHz

Antenna: 8dBi Patch

Lens: f2.97 “wide”

From Rangevideo.com

Camera: 420 TVL 1/3” SONY CCD CCTV Camera

From ClasOhlson.se

OSD: Flytron Simple OSD Ultralight edition + current sensor

Headtracker: Flytron Dt-3k hybrid headtracker

From Flytron.com

Pan/tilt:

1 HS65HB servo

1 HS55 servo

1 sheet 3mm plywood

Other:

6 pairs of Multiplex battery connectors

4 60cm servo extension cables

4 30cm servo extension cables

1 bottle medium thick CA

1 bottle accelerator for CA

Everything arrived just fine and I started the build with the FPV pod;

3mm plywood

To elevate the camera a bit and have something to hide the filter and OSD in, I built a little box on top of the pod.

I modified this HS65HB which i’m going to use for panning, with a 2.1K and a 1.2K resistor to get 180° of travel. Here is a guide that describes how I did it

This is the 420 TVL 1/3” SONY CCD CCTV Camera from ClasOhlson.se. Stock it’s quite heavy, weighing in at 52 grams, but I’m not going to leave it that porky!

Removed some metal…

I also removed the connector and soldered wires directly to the PCB which I then glued with epoxy.

That’s better! it now weighs 22 grams with a f2.97 wide lens.

The pod is coming along nicely.

A HS55 servo for the tilt.

I modified a R617FS receiver with a “lost package indicator” output

This output is hooked up to the RSSI input on the OSD and displays the true RC link health.

Here is a guide for more info and how to do it

The Simple OSD modified with a “lost package indicator” filter

Here is a review of the Simple OSD ultralight

The 300mW 1.3GHz transmitter that I will modify with a DIY antenna and remove the connector.

I removed the SMA connector and will directly solder the new 1/4-wave lambda antenna to the output.

The input connector removed and the cables have been soldered directly to the PCB, as well as the new antenna.

Here is a guide to making your own antenna and tuning it

I added epoxy to make sure that no solder joint get stressed.

The transmitter done with the input cables braided to reduce interference.

Since the FPV setup is going to be powered by the same LiPo as the RC setup, I needed to make a filter. It’s a very simple filter using nothing more than a couple of capacitors and a coil.

This is the schematic for the filter. In my case I used a 1mH for the coil, 220uF for C1 and C2, 100nF for C3 and C6 and 10uF for C4 ad C5. The capacitors C3-C6 are 1206 SMD size and are soldered directly C1 and C2 as you can see in the pictures.

Here is a comparison shot between the AnyVolt micro and the old DIY filter I made a while back.

Soldered everything up.

Added some hotglue.

Shrink wrapped.

And squeezed everything into the box on top.

It turned out pretty darn nice, in my opinion.

Time to start building the airframe. Since I’ve already made a build log on a Twin Star II, I decided to only take pictures of “interesting” parts of this build.

I placed the servos in the back instead of in the front to get them out of the way and get the CG a bit further back.

I used heat-shrink to around the servos and then glued them in place.

I also extended the battery compartment a tiny bit.

The fuselage glued together.

I made a pair of custom motor mounts out of 1.2mm thick DIY PCB lamination.

I extended the aileron servos with 60cm servo cables.

I extended the motor output cables on the ESC’s and re-shrink wrapped them.

Instead of placing the ESC’s in the motor pods, I decided to place them nearer the inside of the wing.

Before glueing.

After glueing.

A close up of the current sensor and ESC in place.

All cables and connectors in place on the wing.

Started work on the ground station. The patch-antenna will be placed on the the lid of the case.

The receiver in place together with the cables.

I used a deans ultra connector between the wings to power the second ESC and multiplex connectors for the signal wires. If you look closely you can also see that I added a piece of foam as a stop for the battery. This way you get the right CG fast and easy every time.

Hurray, it’s done!

It turned out pretty darn good in my opinion.

FPV pod up close.

Magnet latch on the FPV pod.

I added some clear packing tape over the ESC’s and current sensor.

Pretty clean setup, if I might say so myself.

Each motor draws 14.5A @ 11.7V giving 700 grams of thrust and a pitch speed of 75km/h

The ground station finished up.

The piece of wood and rubber band is used for aiming the patch antenna up or down. Works like a charm.

I hope my friend at www.fullkontroll.se is satisfied with my work.

I tested everything at least 3 times to make absolute sure that everything worked precisely as it should.

Unfortunately the weather was terrible so I couldn’t get any good video before I had to send the plane away. But this video is made with the FPV pod from this project: